Performix Commercial Solutions

In 1972, Plasti Dip International invented and manufactured Plasti Dip®, a multi-purpose rubber coating, for the Do-It-Yourselfer. Although Plasti Dip® became well know as a “tool handle coating”; the Do-It-Yourselfer soon discovered hundreds of new application ideas with outstanding results. Today Plasti Dip® is used in the home and workplace like never before. For example, did you know that Plasti Dip® can be used in shipyards, auto body shops, machine shops, hospitals, and for government applications…just to name a few?

And there is no need to limit your ability to identify possibilities and discoveries with just Plasti Dip®. Today, Plasti Dip International manufacture a wide variety of specialty coatings and adhesives that provide just as many ideas for uses and applications. For example, ReRACK dishwasher rack touch-up is used to make just about any coated wire rack look new. Additionally, Vinyl repair products have almost endless uses… some of them likely not even discovered yet!

Please take a look at the products and imagine the possibilities… and when you experience that “aha” application idea, please tell us about it… we love to hear how The Performix Range of products provide real solutions to your ideas and needs.

Available sizes: 29.3 ml Tube Carded, 355 ml Can, 3.78 ltrs, 19.8 ltrs, 189 ltrs Drum

Plasti Dip International OEM Division specializes in developing, manufacturing and supporting unique, high quality flexible coatings and offer a full line of industry leading coatings or will work with you to modify or "build from scratch" a product that meets your exact specifications, application method, cost and environmental parameters.

Plasti Dip Internation lab staff has over 100 years of combined formulating, application and compliance experience to help you meet your needs in a timely and cost effective manner. They offer custom colour matching, physical testing, prototype services, small sample runs, pre-production assistance.

Industries Plasti Dip OEM Division supports include foam cushioning and protection products, concrete, steel, glass, wood, fabrics, plastics and electronics to name a few…

The OEM Division supplies industry leaders in manufacturing of:

Medical positioning products for Operating Room and Imaging products

EMS

Sound deadening products used in heavy equipment

Metal Protection

Foam balls and toys Therapy products

Pressure relieving wheel chair seating

Artificial skin for Prosthetics and manequins

Pool and spa products, pool floats, loungers and life vests and spa pillows

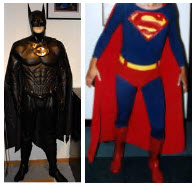

Costumes for theater and various life size characters

Martial Arts protective gear

Military protective gear

Novelty items such as key fobs can coolers, seat cushions Exercise mats and wrestling mats

Concrete and metal applications

Safety coatings/ shatter proofing glass products, light bulbs neon lights and lab glassware.

Electronics

Fishing tackle

Net protection

I.S.S. [International Space Station]

photos courtesy of NASA

Fabric edge protection

Conductive coatings Fire retardant coatings

Glow in the dark

Fluorescent colors