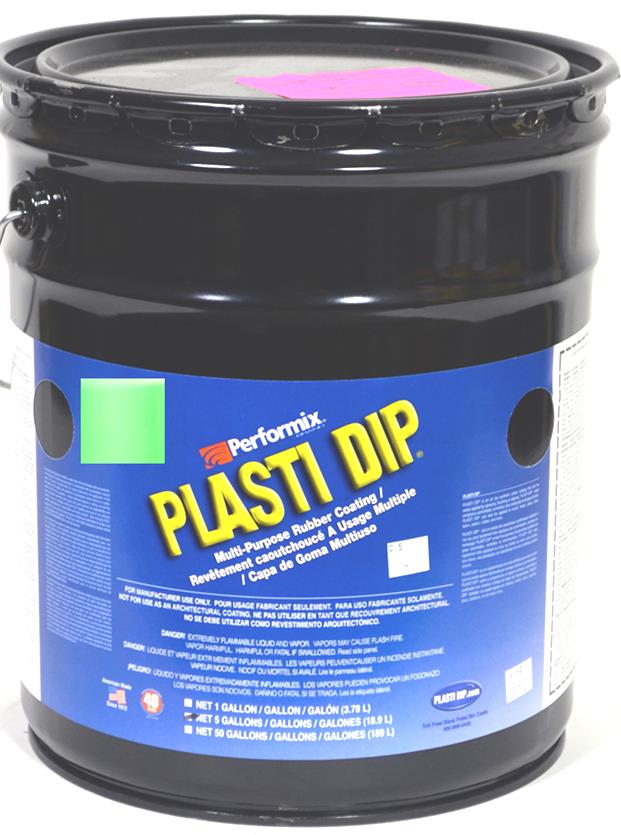

Fl Green PDip UV 18.9 ltr

Plasti Dip® Dip 18.9 litres - Dip or Brush-on

1 x Fluorescent Green 18.9 Litre Performix Plasti Dip Non-UV Multi-Purpose Removable/Peelable Flexible Rubber Specialty Coating Brush-On, Dip. For the brightest possible colours, it's best to apply Plasti Dip Fluorescent Colours over a white base, preferably white Plasti Dip for optimum adhesion.

YOU CAN PURCHASE THINNER IF YOU WISH TO MAKE SPRAYABLE PLASTI DIP: Thin with Plasti Dip Thinner - available in 4 litre and 20 litre cans. It is recommended to thin Plasti Dip 1:1 (1 part thinner to 1 part Plasti Dip). DO NOT use car paint thinner to thin Plasti Dip. 1 x 18.9 Litre Plasti Dip UV Flexible Rubber Coating and 1 x 20 litre Thinner makes 37.8 litres of Sprayable Plasti Dip at recommended 1:1 thinning ratio. This is sufficient for 3 small to average sized vehicles.

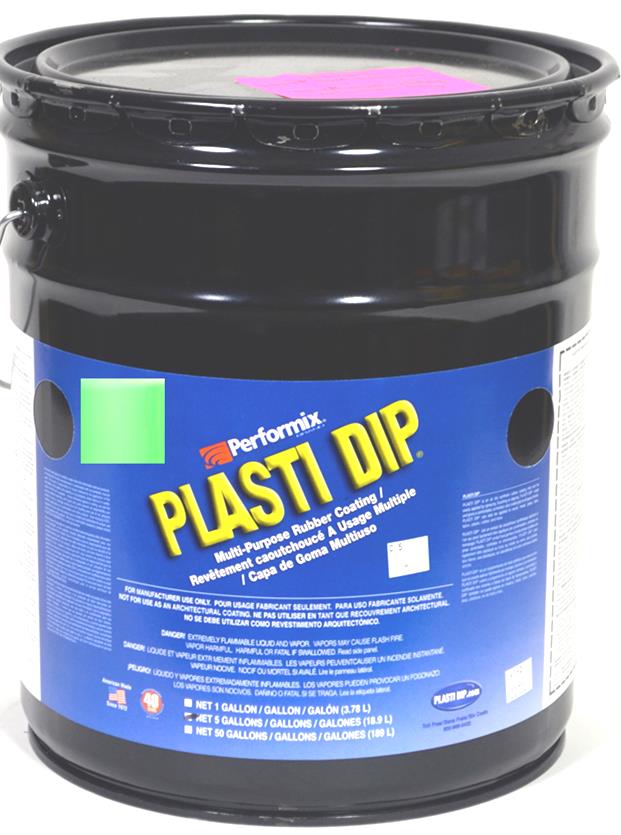

Plasti Dip® Dip 18.9 litres - Dip or Brush-on

1 x Fluorescent Green 18.9 Litre Performix Plasti Dip Non-UV Multi-Purpose Removable/Peelable Flexible Rubber Specialty Coating Brush-On, Dip. For the brightest possible colours, it's best to apply Plasti Dip Fluorescent Colours over a white base, preferably white Plasti Dip for optimum adhesion.

YOU CAN PURCHASE THINNER IF YOU WISH TO MAKE SPRAYABLE PLASTI DIP: Thin with Plasti Dip Thinner - available in 4 litre and 20 litre cans. It is recommended to thin Plasti Dip 1:1 (1 part thinner to 1 part Plasti Dip). DO NOT use car paint thinner to thin Plasti Dip. 1 x 18.9 Litre Plasti Dip UV Flexible Rubber Coating and 1 x 20 litre Thinner makes 37.8 litres of Sprayable Plasti Dip at recommended 1:1 thinning ratio. This is sufficient for 3 small to average sized vehicles.

MULTI-PURPOSE RUBBER COATING

Plasti Dip is an air-dry, specialty rubber coating. In fact, it’s the original peelable, flexible, insulating, non-slip, durable rubber coating. The Plasti Dip product line provides a wide range of coating solutions from automotive customization to home improvement.

ATTRIBUTES OF PLASTI DIP®

- Use Plasti Dip Fluorescent anywhere you need bright, easy to see colours—you can use it to improve visibility for safety concerns, to add can’t-miss colour to frequently misplaced items, or for a one-of-a-kind look on almost anything, from automotive projects to outdoor gear to arts and crafts.

- Plasti Dip Fluorescent available in seven eye-catching colours. The Fluorescent collection applies to nearly any substrate material and creates a protective coating to shield against abrasion, corrosion, mild impact and the elements.

- Plasti Dip Blaze also creates a soft, easy-grip surface that helps prevent skidding and slipping.

- Plasti Dip coats and gives a comfortable, controlled, colour coded grip to all types of tools: lawn and garden, mechanical, electrical, woodworking and masonry. (Non-skid grit can also be added.)

- Insulates electrically and thermally. Dielectric: (ASTM D-1 49) 1 ,400v/mil

- If the coating gets damaged or wears out, or if you just want to change the look of your Plasti Dipped project, Plasti Dip Gunmetal peels off easily from most surfaces, leaving the material underneath in its original, pre-Dipped condition.

- Peelable and removable from of most surfaces

- If you require a permanent coating - surfaces which are non-absorbent such as metals should be primed using our recommended Primer which is available in a Clear colour 311 gram Aerosol. DO NOT use Primer if you wish to remove the Plasti Dip in the future.

- If the coating gets damaged or wears out, or if you just want to change the look of your Plasti Dipped project, Plasti Dip peels off easily from most surfaces, leaving the material underneath in its original, pre-Dipped condition

- Remains flexible and stretchy over time

- Will not crack or become brittle in extreme weather conditions

- Proven in temperatures from -30°F to 200°F (-34ºc to +93ºc.)

- Plasti Dip can be easily applied by dipping, brushing, or spraying (thin with Plasti Dip Thinner for spraying - available in 4 litre and 20 litre cans).

- Plasti Dip protective coating is ideal for a broad array of do-it-yourself projects around the home, garage, garden and elsewhere. It protects coated items against moisture, acids, abrasion, corrosion, skidding/slipping, and provides a comfortable, controlled grip.

- PLASTI DIP® is not just for tool handles. Paint onto, spray or dip almost anything! Add more layers for greater protection or grip. Plasti Dip can be used on Paper, Tools, Arts and Crafts, Lawn Equipment, electrical connections, Rope and Fabric, Wood, Metal, Glass, Plastics, Rubber, Fibreglass, Chair and Table Legs…. and more.

- WOOD: Seals and protects from weathering and prevents splitting.

- METAL: Reduces vibration, deadens sound and prevents corrosion.

- GLASS: Shatter proofs glass objects (available in clear).

- Also... PLASTIC, RUBBER, FIBREGLASS and CONCRETE SURFACES!

- Structural concrete: Sealing block walls - Roadway structures - Swimming pools - Foundations - Fountains - Walls and ceilings in processing plants - (wherever concrete deterioration is a problem)

- Structural Steel: Joists and Beams - Metals (subjected to any corrosive environment) - Bridges - Cushions Hand Rails - Railings - Storage towers - Below ground tanks - Exposed machinery

- Wherever metal is attacked - Plasti Dip performs! Transformers, Cables / Straps, Rope, Wood, Joy Sticks, Circuit Boards, Electrical Boxes placed on the ground, Magnets, Stove/Oven handles, Fabric, LaCrosse Sticks/Nets, Astro Turf, Food Grade Barrels, Crutch Handles, Control Boxes, Relay, Electric Winch, Metal Grates, Sharp edges, Pumps, Hand Tools, Valves / Actuators, Curtains, Pulleys & Rings, Clips, Poles, Glass, Underground tanks, Pipes, Hardware & Metal surfaces to prevent electrical discharge & sparks.

- For coverage and other technical information, please refer to the Manufacturer's Technical Data Sheet, Tips, FAQ and 1001 uses sheets.

- See product labels for further information.

- Not only is this stuff good, IT'S FUN!!

MOTOR VEHICLES

- We recommend you wash the vehicle or item with warm water and dishwashing liquid. If there are any greasy or waxy areas we recommend using rubbing alcohol to remove them. Do not use a car wash with silicone before spraying as Plasti Dip will not stick to silicone.

- We recommend 5-7 spray coats of Plasti Dip to ensure a thick enough coating so that it can be easily removed if/when required. It will take approx 4 spray coats to start to get good coverage.

- We DO NOT recommend you use Prepsol as this causes static to build up which gives a very rough, furry finish to the Plasti Dip.

- Mask up any areas that you do not want coated and cover your wheels, brakes, etc., if you are not removing the wheels.

- The Plasti Dip can then be applied. You will need a HVLP spray gun that will run at 20psi with a 1.3-1.5mil needle, maximum 2mil needle.

- The Earlex MS2901 HVLP Spray Station Gun is specifically designed to apply Plasti Dip and is available here.

- If the Plasti Dip comes out of the gun at a high psi the Plasti Dip will dry before hitting the surface and will give a sandpaper finish. It is recommended that the spray gun be held 6-8” away from the surface, otherwise the Plasti Dip will dry before hitting the surface and give a sandpaper type finish. If you get runs you are probably too close or spraying too heavily.

- It is recommended that you remove any tape whilst the last coat of Plasti Dip is still wet to avoid the Plasti Dip sticking to the tape.

- Average Usage: